And ‘tis not even St. Patrick’s Day, begorrah.

I’ve been watching the YouTube modellers painting their planes and cars and musing about the business of the production jig. You’ve read about this before here in the Little World as I glue together bits of foamcore board to support aircraft during the painting process. I think it may be an art and science that would pay study.

Part of that study could be directed to the factories that made real panes back in the day – the California plants that turned out fighters and bombers in such vast rows. They jigged their assemblies to aid in rapid manufacture, but the shapes they devised to do it could also be adapted to ensure good model making.

I primarily deal with propeller – powered aircraft that do not have nose intakes or jet exhausts. Thus I am denied the opportunity to stick a dowel up the bum of a Beechcraft and use that as a handle to rotate the assembly in front of the spray gun. Up until now I have sometimes been able to make use of a single propeller position on the nose of a fighter – either a protruding shaft or a hole disappearing into the engine – to suspend the aircraft horizontally.

This, however, does nothing for a twin-engine job…and when I get to the Lancaster/Stirling/Liberator stage the whole thing will become very tricky. I need to start planning for those constructions now.But I want to find a way of doing it on a modular basis that can be reconfigured for ach different plane.

I think it is time to look at the jigs and benches employed by the builders of flying R/C models to see whether there is something there, Also to scour the net for other plastic modellers who have drawn up designs.

The main problem is the points of contact that the jig has to make on the model:

a. Gluing jig – no problem – all it’s got to do is hold the parts in the correct position while the adhesive sets or evaporates. I’ve been taping fuselages to the building board ever since I started. I’ve also seen an ingenious worker on the internet use Lego blocks to build up jigs for his wings and tailplanes. Clever man, as the blocks are re-usable.

b. Painting jigs are harder – because we want to the paint to flow evenly around the aircraft without being cut off in mid-spray. So far balancing the model on foam blocks set into the landing gear bays seems to be working if there is no hole in the front of the engine compartment for a tube suspension.

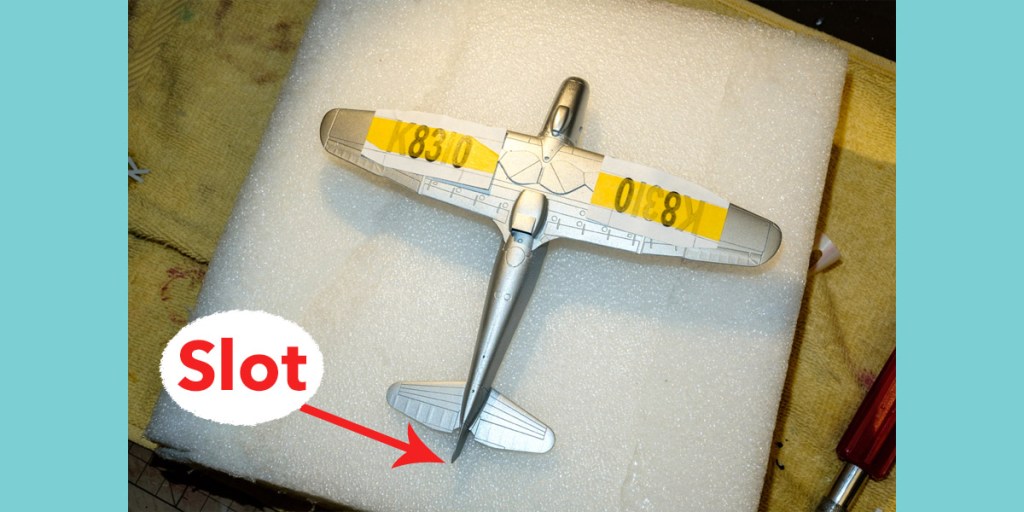

c. Decaling and lettering jig – My friend Warren scored a big block of resilient foam from a packing crate and cut me off a piece. I ran a slot down the centre part of it and it is now perfect for gripping vertical stabilizers or wings to allow you a steady hands-off platform. Such a simple solution…

Funnily enough the dear old Airfix/Revell/Aurora clear plastic airplane stand would be a help in the painting. If you were prepared to accept the slot in the bottom of the fuselage you could get to all of it with a spray easily. But they don’t give you a free stand anymore.

Leave a comment