I started my search for the perfect gap filler to make my plastic models seemingly seamless a long time ago. Well six years or so, anyway. When there was still Stanbridges – Elvis and dinosaurs having passed away.

The first tube I bought was from Tamiya, and unlike most of their products, was far from excellent. It was barely usable – stiff and sticky at the same time, but not when you wanted one property over the other. I persisted with it until I could not stand the stuff any more. Contrary to my nature, I dropped it in the bin.

The next goo was better – John Evans introduced me to Perfect Plastic Putty and it filled up many a seam. Perfect, until one had to scribe over it…and then the friable nature of this water plaster meant that the scribed lines were terrible.

Third trial was with Mr Dissolved Putty. This shot down cracks, hardened, shrank, and had to be repeatedly applied. Not too bad, though, for minuscule flaws that could not shrink.

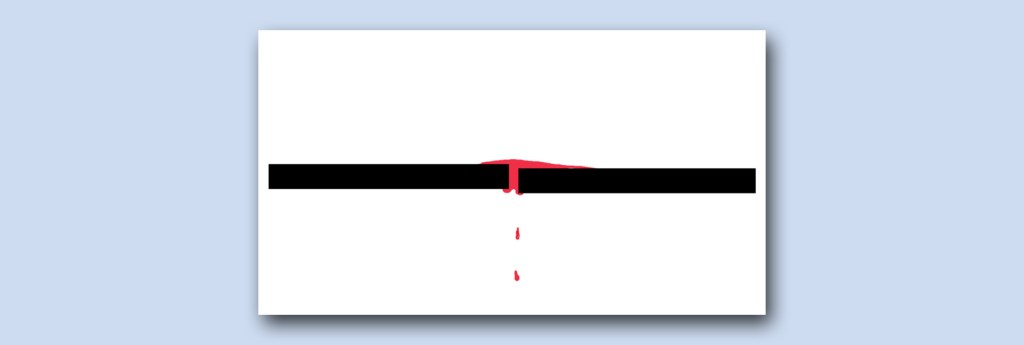

The use of Zap-A-Gap for filler is still under trial. it certainly strengthens the joints and can fill up deep ones. It’s hard to sand without ditching, however, and nearly impossible to scribe. I now think of it as the bottom suture in the wound upon which other materials are placed.

Did I succeed with the squeeze tube of Vallejo acrylic? I some wing root fillets, yes. You can syringe it into them and then let it sit for two minutes. Follow on with a dampened Q-Tip swab and you may not have to do anything else at all for a perfect seam.

Now I am trying the redoubtable Mr. White Putty for big areas. It can be cut with levelling thinner to make a paste that can be paddled over a considerable area. The secret is a large, flat, clean mixing spatula to trowel it on with an occasional dip into the thinner to make the surface smooth.

I still appreciate mould makers who can give me a basic airframe that doesn’t have ditches on every corner. I have also learned the trick of getting top surfaces perfect – even at the expense of the lower ones. We see the top…

Leave a comment