I washed the kit parts for the Henschel before dinner – they sat drying as I browsed and sluiced, and were ready for a start as soon as the coffee was served.

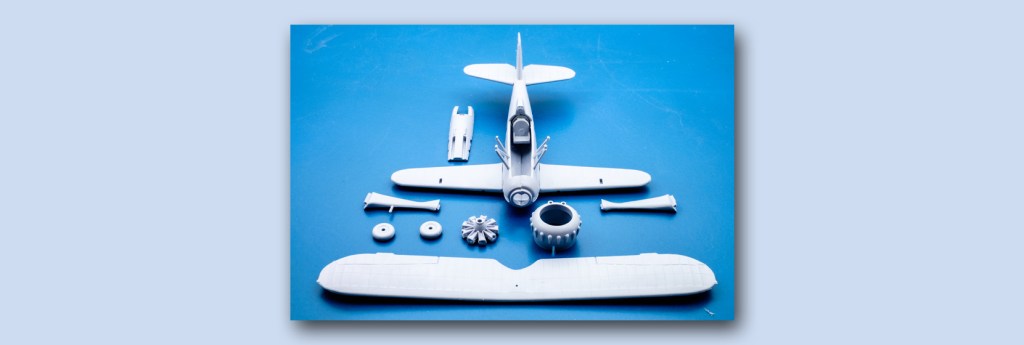

What you see in the heading image is less than two hours later – all the major parts de-burred, edge-cleaned, and assembled. Tomorrow will see the painting begin on the interior of the fuselage and the wheel spats and I expect that the plane will be ready for undercoating at the end of the the evening.

Now the question arises as to whether this is a good thing. There are two schools of thought:

a. It is terrible as the model is not complicated enough. It should take weeks to add extra pieces bought from independent suppliers. If you don’t do this, you are just a kit assembler.

b. This is wonderful as the kit is basically sound. All the joins are close-fitting and there are few sink marks or ejector pin remnants. The kit makes a tiny model and has all the detail that it can decently carry.

I am just delighted with the precision that Airfix could produce for this money fifty-one years ago. Would that their eastern European competitors could do as well right now with new tooling.

This sort of facility in model building suggests another interesting approach; parallel builds. If the price of one of these kits is low, and there are several schemes presented that look rewarding, why not get two or more of the same kit and build them as a complete batch. If you use the box decals you’ll have four sets for two planes and this is good insurance against folding some detail onto itself.

You certainly couldn’t do it with a battleship festooned with brass photo-etch, but for a 1:72 plane it’s perfect.

Leave a comment