Sounds like a political party that’s going to lose their deposit, eh?

Well, it’s a good idea for scale modelling when the makers of our kits decide to care less about them than we do. When they mould things too fast and the plastic warps out of the blocks. When the parts only fit where they touch and they don’t touch…

I picked it up from the schoolteacher chap on Phil Flory’s channel. He was faced with an Me 109 kit that was more warped than the Third Reich – but rather than bin it, he saved the build by progressive cementation.

He started at the tail and achieved a good joint on the two halves of the rudder and vertical stabiliser – without extending the cement bond any further forward. He let it set firmly for a couple of hours, then approximated the fuselage behind the cockpit and cemented that. Ditto – with time for setting – with every separate portion of that fuselage…until it was all closed on itself with no ledge or trench.

There were probably fierce stresses in the thing by the time it ws all clamped and set, but they are not likely to twist out now that the thing is a monocoque,

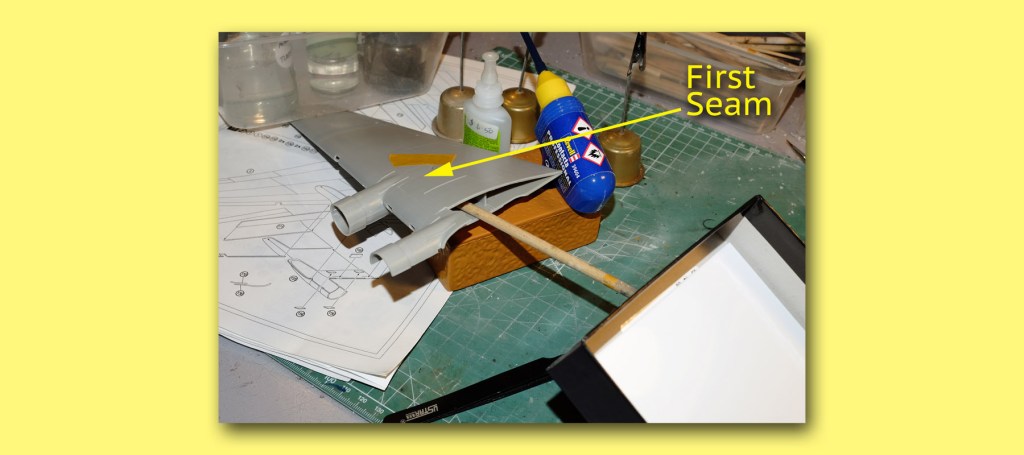

I am applying it to a big wing that has engine mounts top and bottom . None of it would be possible in one go, but slowly I will stitch up the seams. A tack with superglue and a flood of super-thin.

And had the manufacturer slowed the production line by 30 seconds…none of it would be necessary.

Leave a comment