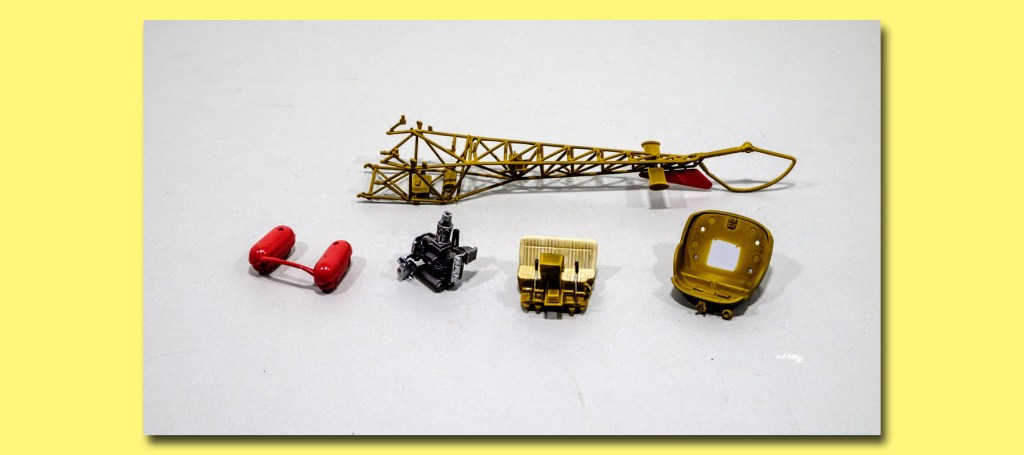

The idea of serial building is working out, but there is still a place for sub-assembly lines in the scale model factory

Even with modern super-glues there is still time required for re-enforcement to set, and of course the drying and setting times of the various paint coats. So there is a real advantage to having several assembly lines in operation.

The Bell 47 lent itself to this admirably. The basic cutting and cementing was done at a library modelling afternoon and the next day the various sub-assemblies could get their paint coats. It is amazing how fast this can happen if you are ready with the various bottles pre-shaken or stirred and can move between colours with a rinse of the cup.

Rule is light colours first and then darker ones. Especial care taken to rinse the cup after a metallic paint.

A warm box in cold climes is a good, but a warm box with a flow through of air is even better. With the use of Gunze Rapid Thinner you can almost pick up a piece as soon as you have finished another. This works best if you are trying for a flat finish.

Leave a comment