You have to confront your fears as they come up.

Or run away. I have been dreading the missing/broken/spoiled canopy situation ever since my first cement fingerprints on a P-47. I hasten to add, that was when I was seven – I now glue the little beggars on with PVA glue and all is serene.

But what if there is nothing to glue.?

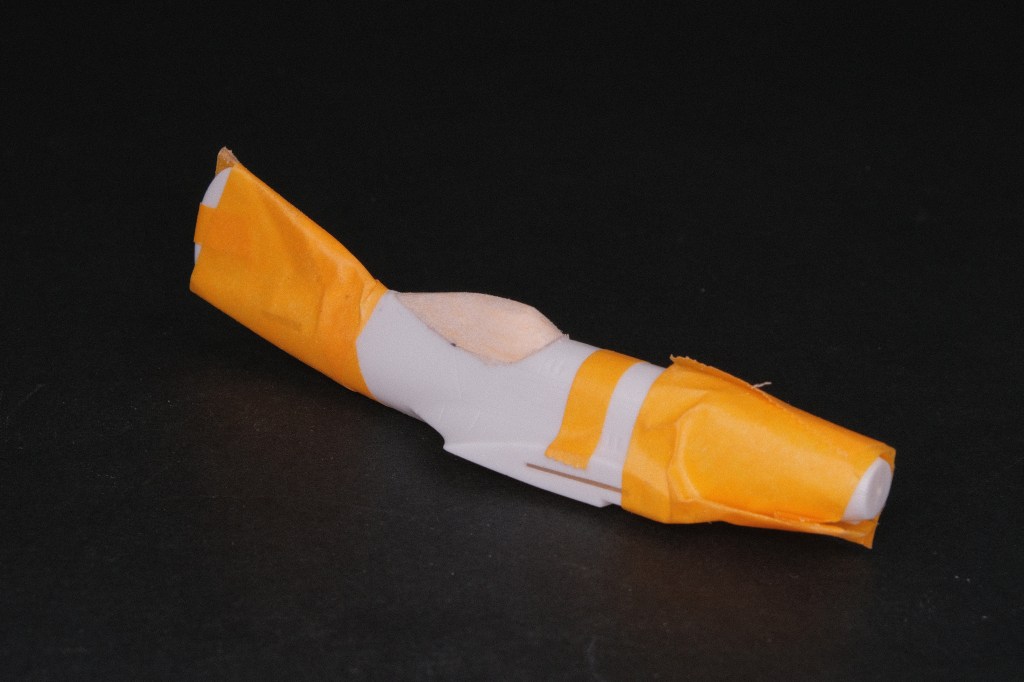

Forced to it. I temp-bonded a block of balsa to the fuselage of this MiG model and started carving. It was surprisingly easy with a sharp blade and eventually I ended up with a wooden master in place.

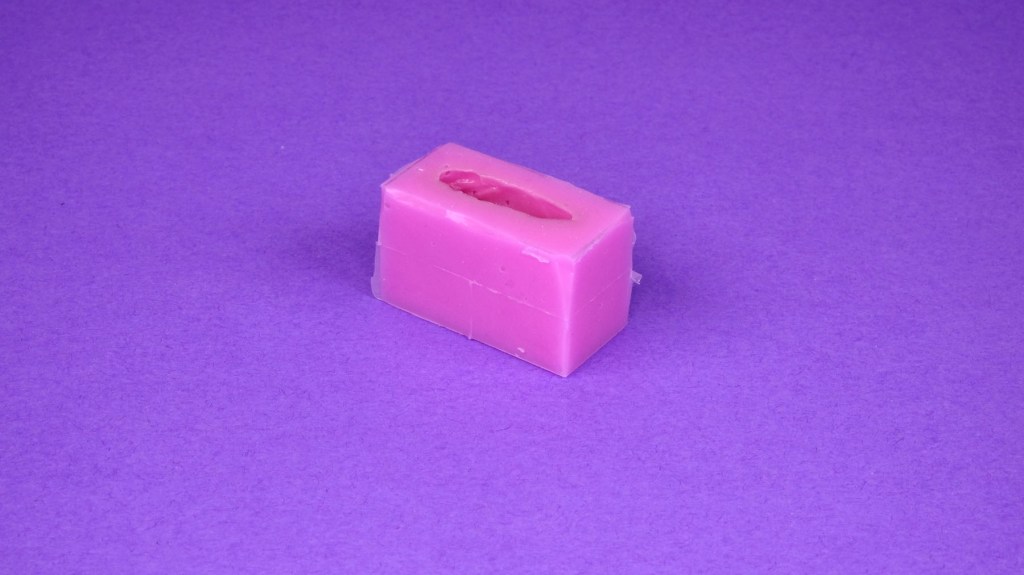

At this point I could have plunge or vac-moulded it if I had the materials and gear. I elected to use pink silicone rubber to make a negative mould of the master. A temporary cofferdam of cardboard and putty let me pour round the balsa and I had a usable mould in an hour.

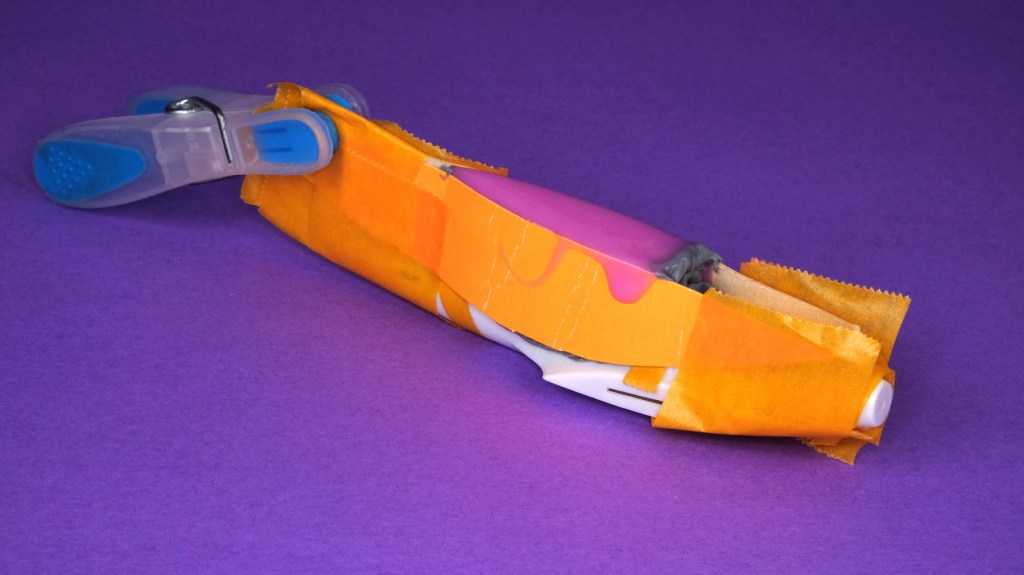

Then the problems – the 2-part epoxy resin from Spotlight could be mixed clear but the shape of the negative mould did not allow it to fully fill the cavity – it just ran off the sides. Failure No.1.

Back to the master model – and thus time boxed in a LEGO holder on its own – no fuselage. This sort of mould is more familiar to me from practice days.

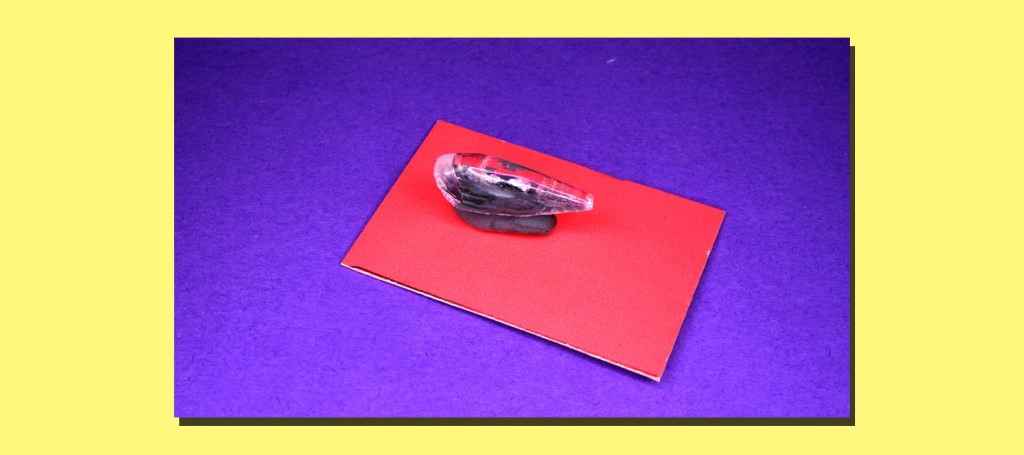

The epoxy resin went in again and all bubbles were teased out. It set overnight and could be popped out next day and the base cut off with a sanding drum.

The final polish was applied with a clear lacquer coat – once it’s in place I’ll draw on the frame lines.

Not a perfect canopy, but a pretty good learning experience.

Note: Spotlight also sell a UV-curing clear resin that you might be able to slosh around inside that original mould and then zap with their portable UV light pen. That might make a hollow clear canopy…

Leave a comment