Who said he had discovered 10,000 ways that you could not do something before he made a successful electric lightbulb?

I feel like that sometimes dealing with the scale modelling world. Whether it is painting or moulding, soldering or carving, there seems to be a long and winding road always ahead of me.

A case in point is the little freebie kit of a MiG 3 fighter plane. All fine except for the missing canopy. The hardest thing to source or make and the one thing that nearly always makes or breaks a build.

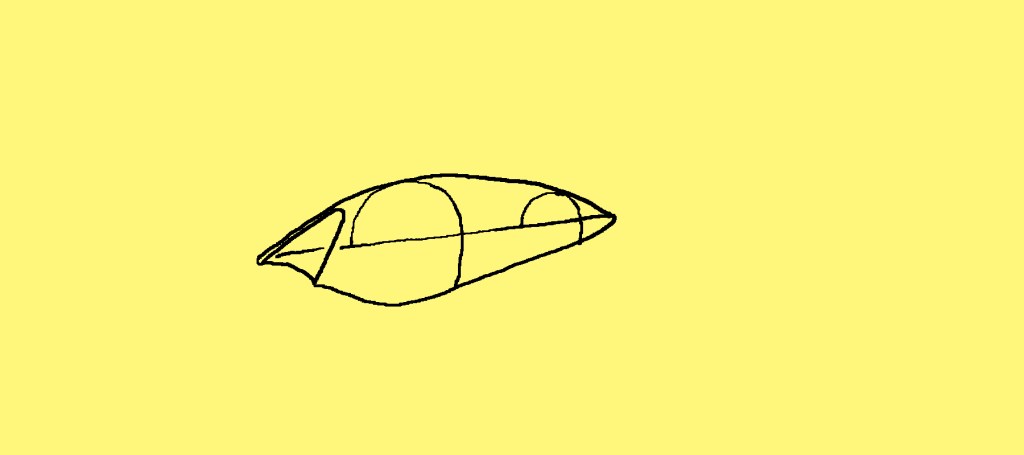

Not content with the coward’s way out – tarping the cockpit – I decided to try moulding a new one out of clear epoxy resin. Balsa block temporarily glued to the fuselage and carefully carved and sanded to shape. Then a temporary cofferdam around it and pink silicone poured in for a flexible mould.

All good, except the shape of the thing could not hold the clear epoxy long enough for it to set. Failure No. 1.

Second silicone mould with the master model embedded in it in a conventional way. Have to wait a day for the slow-setting resin to harden, but at least it does look extremely clear.

If this is a flop I will have to try either plunge-moulding the canopy or painting the inside of the mould with UV-setting resin. Adversity is possibly good but you can have too much of a good thing.

Leave a comment