The preliminary work on a model is sometimes the hardest thing to do – and this applies to big scratchbuilds as well as to the humble kit. As well, there is always something that you like doing least of all in the workflow. It can be planning, marking out, jigging, sub assemblies, or repetitive part making. Human nature being what it is, the Little World builder will shirk from the task they don’t like…and it will just loom larger and larger…

I used to build large ships, and some of their hulls were done by the technique of bread-and-butter buildup…and then carving back. I hated it and was always terrified that I would ruin the job by bad carving. There were lots of profiles that could be made to prevent this, but I never really got to the point where I liked the task.

Modelling large-scale houses and buildings has a stage that involves window making that seems to go on for decades. I know it is just a couple of nights but the cutting and fitting of tiny bits of wood is very boring. I have to do it because my chosen scale is not catered for by dollhouse makers.

The 1:72 airplanes are mostly good, but I do get a tad impatient waiting for one coat of paint to dry before adding the next. My shed, however, does its best to help out as it can get very hot in summer. 6 hours will bake most acrylics as tight as ever they will be and even some enamels are safe in that time. But every now and then I discover one of the disadvantages of choosing such a small scale – the makers get overly enthusiastic about tiny and thin parts.

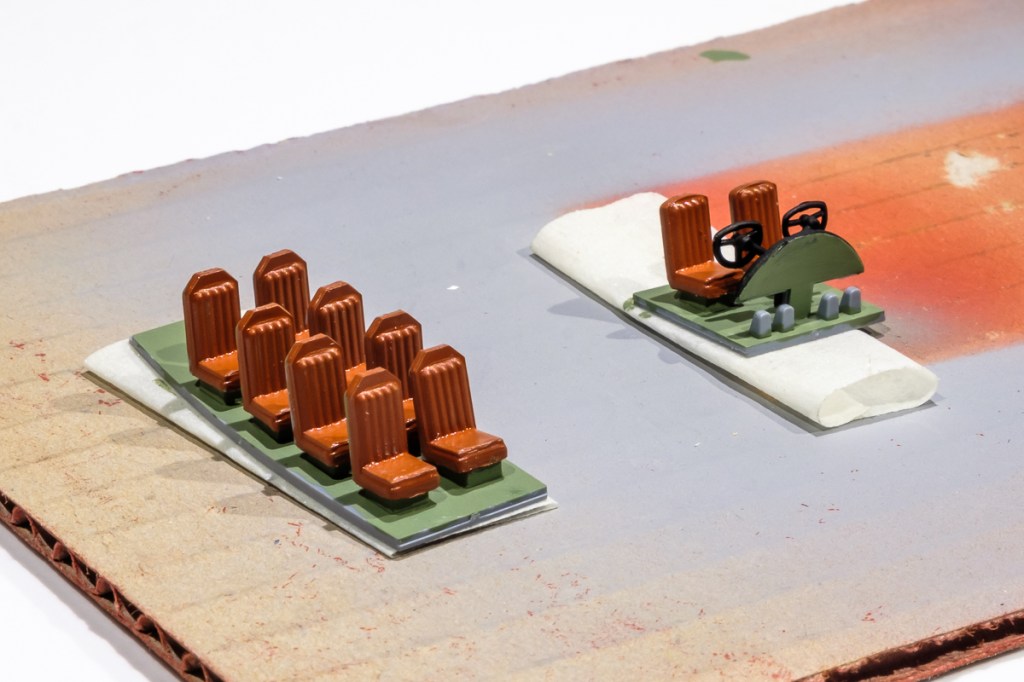

The seats of the new Northrop Delta 1D are fine – the red colour is supposed to be leather. The instrument panel fitted well and the control wheels are a joy…but they are only a joy if you are prepared to super-glue them in. Cyanoacrylic cements are wonderful if you are the sort of person who likes playing with razor blades and loaded pistols. I encountered them firstly in 1972 when they were marketed as a denture repair alternative and I watched people destroy their false teeth for at least a decade with them after that. They did have a place in the dental laboratory, but not in the patient’s mouth. They certainly had a place on the fingers of the modellers. and the fingers had a place wherever they touched…

But you can’t ask the stuff to do a job that the substrate won’t support. Case in point is the wheel struts of the Delta 1D. Those little “y”shaped pieces are meant to support the entire weight of the model on the two main wheels. They disappear up into substantial spats attached to the wings but the variant I am building has the wheels practically exposed. Those parts are broken and distorted on the sprue, but even if they were perfect, they are far too flimsy for the job. I’m still debating on how the wheels can be supported and suspended – I suspect wooden blocks hidden in the spats and then some wire struts for the look of the thing. Not successful, Special Hobby…

Leave a comment