I was right about the quality of the Tamiya kit – the first encounters at the dry-fit stage were excellent. No flash whatsoever, and small casting gates. In most cases the precision shears were all that were needed to separate the parts with no additional mangling.

The cockpit has a great deal of detail without going over the barrier of sense – all the parts were out of the box with instructions about colouring and the whole tub is so accurate that it slots into the fuselage without additional hacking anywhere. I even tackled the decals for seatbelts – on the theory that even if you don’t see too much of them under the canopy, the exercise would still do me good.

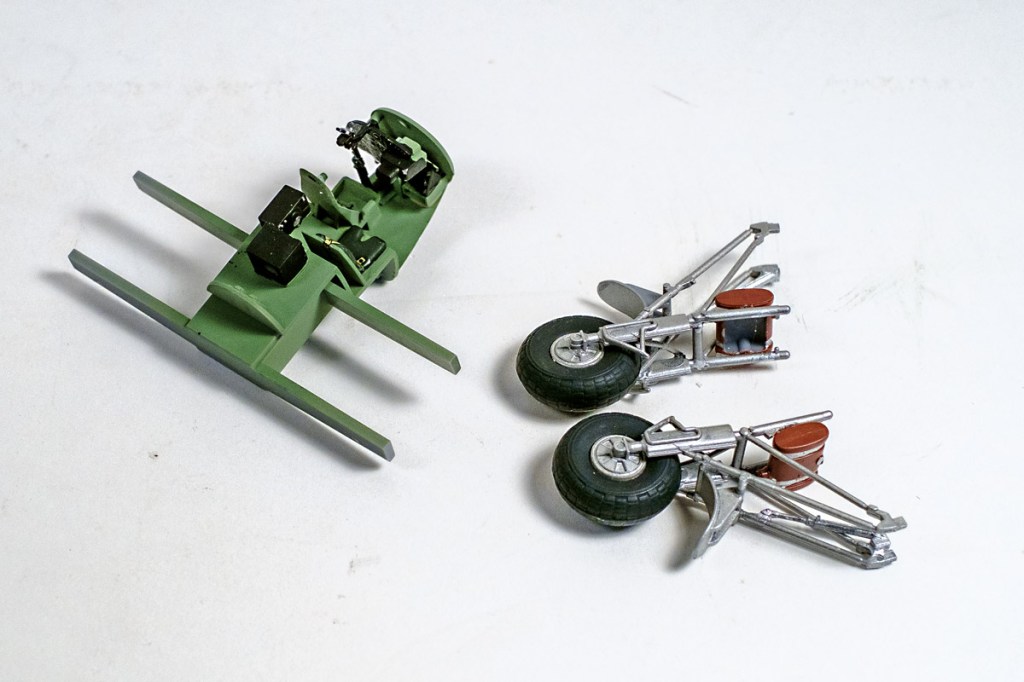

The landing gear was a little daunting when seen on the sprues – I thought it looked spidery and difficult – in the event it proved to be nothing of the sort. With a spray job on the sprue and a little cleanup later, all that was needed was some thin cement at the attachment points and the cages just fell together. I didn’t have the heart to flatten the tyres, but I’d consider it on another model.

Is I’ve written before, a good model-building experience is comprised of a number of good sub-models – if these are rewarding they encourage you to gallop to the end. These are just what I needed to encourage me!

Leave a comment