Getting a kit that is deeply flawed – or undertaking any other modelling task that is doomed to failure from the start – is a wonderful opportunity to put the prop on coarse, turn on the water injection, and shove the throttle past the military stop. You might as well see what the hell happens…

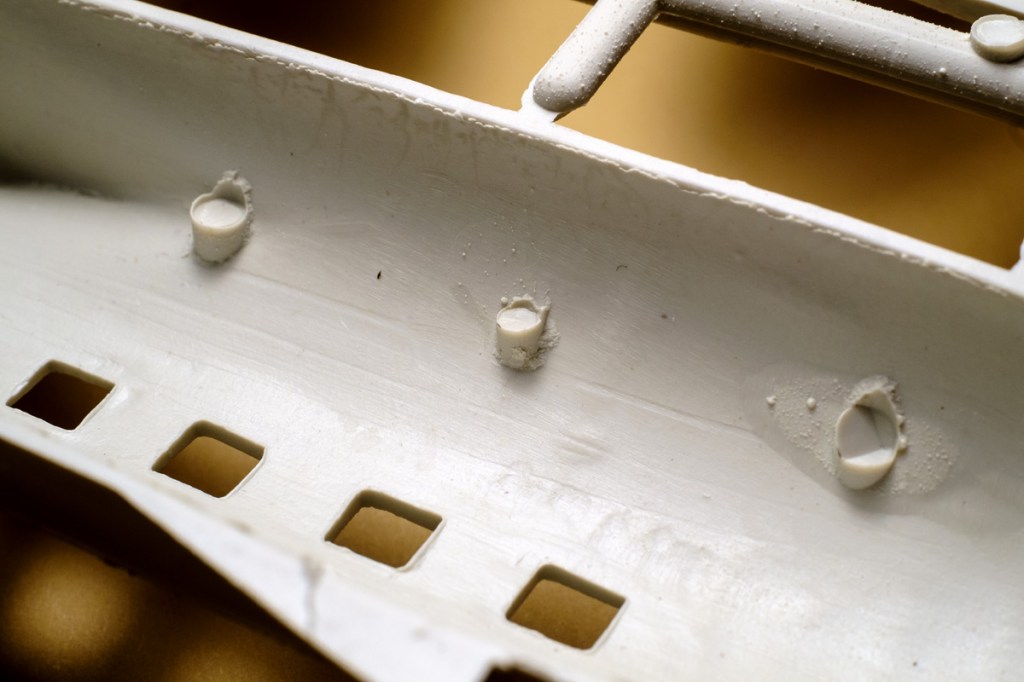

In the case of the Convair 440 – which is not as hopeless a kit as people would have you think – I have been confronted by crude castings, strange plastic, and broken parts. This means it cannot be built in the normal fashion. Which gives me carte blanche to be abnormal. I have a head start in this as I know any number of abnormal friends, one of whom is reading this column right now…

The windows of the Mach 2 kit are a separate sprue of semi-clear styrene. I say semi-clear, as they are not quite good enough to see through and not quite good enough to block out all the light. The cabin windows – 12 on each side – are small rectangular bits that promise to fall into the ugly, empty fuselage at the first opportunity. So I have decided to blank them off and fake them up.

I glued a strip of white styrene inside each fuselage half with Humbrol Poly – figuring that it would have the chemical oomph to dissolve the Mach 2 plastic. But then to reinforce it I used a hot glue gun to seal the strips in. Thus is the first time I have been able to use this tool for any modelling. As long as something is crude and hidden it seems a very good idea. And so quick.

Second problem was a fractured wing – one of the under panels had been snapped cleanly. Okay – that meant that it could be glued cleanly but one couldn’t trust it to support weight. So each hollow wing received a piece of wooden venetian blind as an internal skeleton – again one part of this was bonded with hot glue. All hidden and all solid.

For the nose weight I flattened a musket ball, cut it up into small chunks, and poured them into the nose – sealing it with Uhu yellow-tac. I have a large supply of musket balls left over from fighting the Indians. We have made peace and I call at their $ 2 shop every month for little accessories.

But the best idea for an unusual solution to a potential problem was provided by John at the modeller’s club. He’s got some Mach 2 models and is a little skeptical about adding enough weight to put the nose down – he looks at the landing gear and can see it bending under the weight. I think he may be right.

So he cheerfully glues a clear plastic prop under the fuselage a little aft of the balance point to keep the nose down. I made a wry face at this idea until I looked more closely at a Mach 2 model Argosy freighter that was sitting in the club display cabinet. It had the discrete plastic prop – and I had been looking straight at it for weeks without seeing it. So much for being all fussy and worried. I think I will adopt his philosophy in the future.

Leave a comment