I am never loathe to accept advice from people who really know how to do something well. Not so sanguine about being told off by those who have never done something themselves, but I’ve learned to put up a poker face and not react. Eventually they go away and I can get on with it.

The good advice in this case came from Mark Bivens – a friend of my mate Warren, who has a trick for making the tailplanes of his models turn out well. He realised that in many cases the best way to attach the horizontal stabilizer components was before the fuselage halves were mated together. The central seam line for nearly all models is a flat plane directly down the middle. It might be interrupted with little plastic nubbins and sockets – as in the older kits – but when it is clean, it is the most basic datum line for the aircraft.

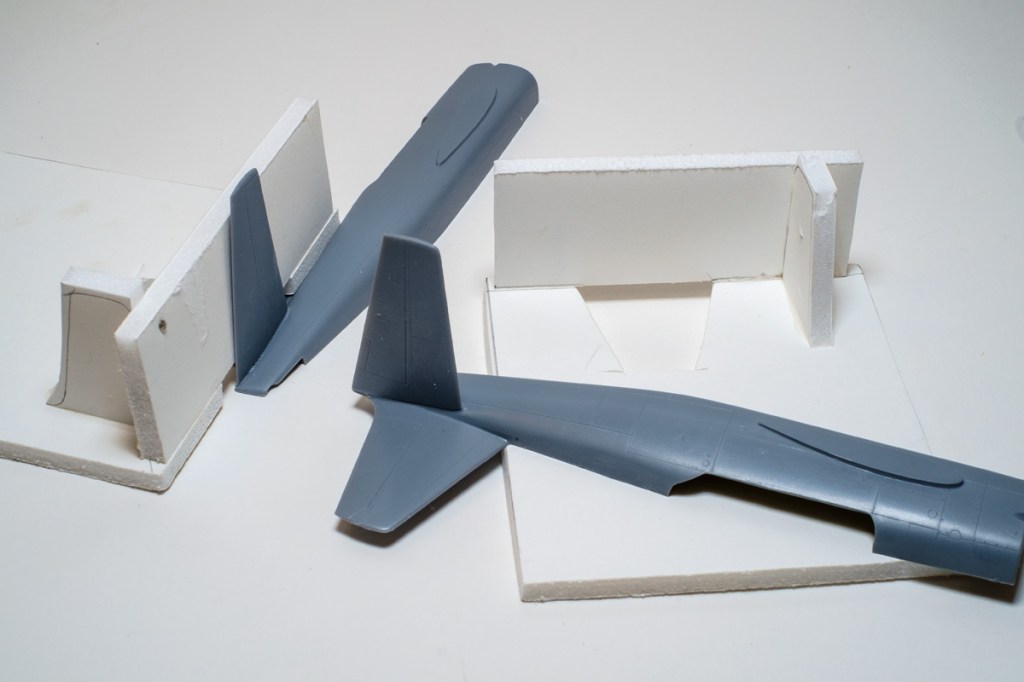

Mark capitalises on this when he needs to attach the stabilizer by making sure the part is 90º to the surface that supports the fuselage…and then each part is straight according to the wings and to each other. AIrcraft that have a positive or negative dihedral to the tailplane are exceptions, but here you can make special jigs.

” Is this needed? ” I hear you ask…considering the fact that some makers produce a tail part that tabs into a slot in the fuselage. No, if you can trust the maker to get it right. Sometimes they do not…and somtimes plastic warpage takes away what precision they tried to mould in. So you are back to fixing it yourself.

I use a giant whiteboard with a solid backing as my basic building and datum surface. I can put triangles, set squares and engineer’s blocks on it to ensure that buildings and vehicles are built square. It’s a leftover from my wife’s club secretary days and is a very welcome thing – not least because you can wipe paint off it without any damage.

The jigs to set the stabilizers were made of my favourite leftover foam-core 10mm board held together with white glue and pins. It’s a great way to build as it is fast enough yet precise enough to satisfy all needs. Once the stabs were glued up with thick cement, they could be propped and taped into place and left overnight for a perfect job in the morning. Precision for nothing!

The wings will be a tougher proposition, as they will need to go on when the fuselage is closed up. But no doubt foam-core board will make an appearance again with a lot of measuring and squinting. It must have been a lot like this in California in the 1940’s…you know…before they banned plastic straws…

Leave a comment