You can’t get away from the fact that the Junkers people – like Henry Ford and the Citroen car designers – knew a thing or two about the way materials behave – in particular on how to make a sheet of metal stiffer than you’d expect. Simple. Bend it in repeated folds like a corrugated road. it’ll still bend easily parallel to the folds but won’t bend at all at 90º to that. And then you can run the stiff length wherever you need for an airplane or car body.

It’ll look a little agricultural, but be easy to make and possibly cheaper than trying to beat a compound curve into a metal sheet. If you can only afford a little engine to power it, let it run on the ground – if you need to get it into the air, add more engines.

Thus the covering of the Junkers 52 – corrugated duraluminium on wings, fuselage, and tailplanes. The only elegant curves are in the wheel spats, and possibly in the toilet seat. Everything else is straight lines and wind resistance. I’m surprised that they let themselves go far enough to make the propellers turn in a circle instead of a square…

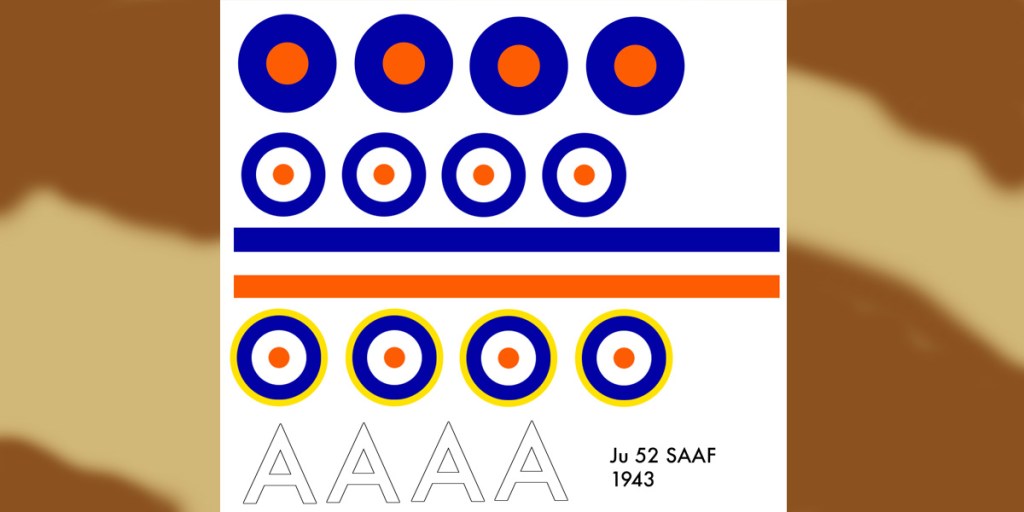

Well, the ” Iron Annie ” has a charm of her own and I would not have it any other way except for the fact that the decals are going to have to go over some pretty rough surfaces. Even coating the corrugations with clear acrylic to give a smoother surface may not allow them to settle into the grooves well enough. Microset and Microsol will be used, of course, but there will still be a lot of softening needed. I may have to accept a little discrepancy or essay to paint the roundels and fin flash myself. As the decal sheet has already been printed, there is no harm in trying them on to see if they settle.

I may live to regret falling for this kit…

Leave a comment