Since being introduced to this material two years ago I have found my respect for it increasing. It’s English and fairly specific to the plastic kit hobby but really does fufil its purpose.

The purpose is best circumscribed – the filling of broad, shallow depressions. It does not form a structural component so you cannot stress it with a great deal of side-pressure once set. – it fractures. But give it a depression to settle into and build it up in thin layers, and it really makes filling easy.

I do not use my finger to shape it as some do. The Ustar spatula lives in my club toolbox and a similar one – relic of dentistry days – in the main workshop’s tool pouches. Handling them is instinctive after 40 years of mixing phosphate cement and zinc-oxide eugenol paste on glass slabs. I use a small tin lid of water to aid the flow of the spatula once the putty starts to set, and I can achieve a fairly smooth surface even before it goes off. Think of it in terms of a very small grano job on a footpath or driveway.

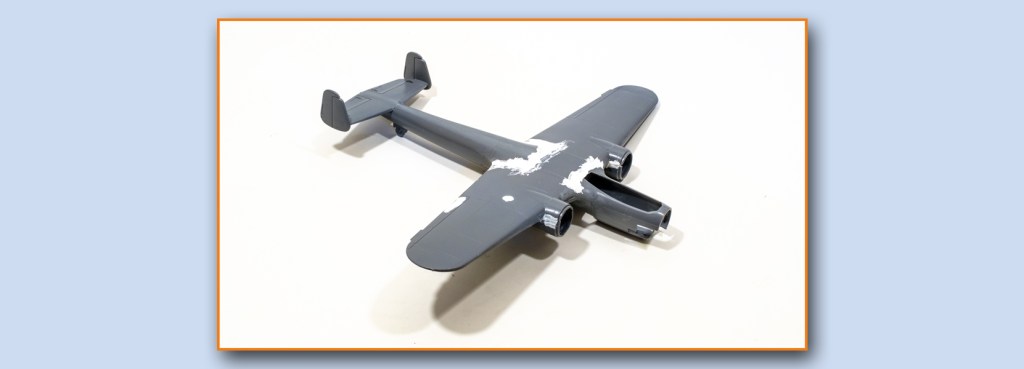

Actually the Dornier needed more filler than I thought. The panel lines fit reasonably well but their final position was well out in two cases. I filed and sanded for a while and then filled the rest. There was even one sink mark and one blowhole – a kit of its time…

Note: I have recently started to use a UStar scraping tool for seam lines and it seems to be doing better than sanding sticks for this sort of thing. I note that there are more expensive tools for this, but that will always be the case in the hobby shop. I prefer the economical option with the reward of a feeling of frugality after I do the same job as I’d have done with the expensive one.

Leave a comment