A Fairey gets its wings…

The magic of scale model building is far greater than any mousey studio could dream up – we actually get to do things instead of just watch other people do them.

One of the things we do is cement wings onto aircraft. We can do this neatly or not, but too little cement and too much dependence upon magic can take the Fairey’s wings right off again.

I try the wing joint on every plane I build at the dry-fit stage and am always relieved if it is a little tight. I welcome accurate fit at the wing root interface, but I can stand a little gapping as long as the thing is stiff enough. The bane of the builder is the moulding design that is just that little bit sloppy or depends upon very thin wing panels.

The best chances are provided by kits like some of the newer Airfix designs that provide wing spar stubs keyed into the fuselage halves that also establish the dihedral and wing root interface.

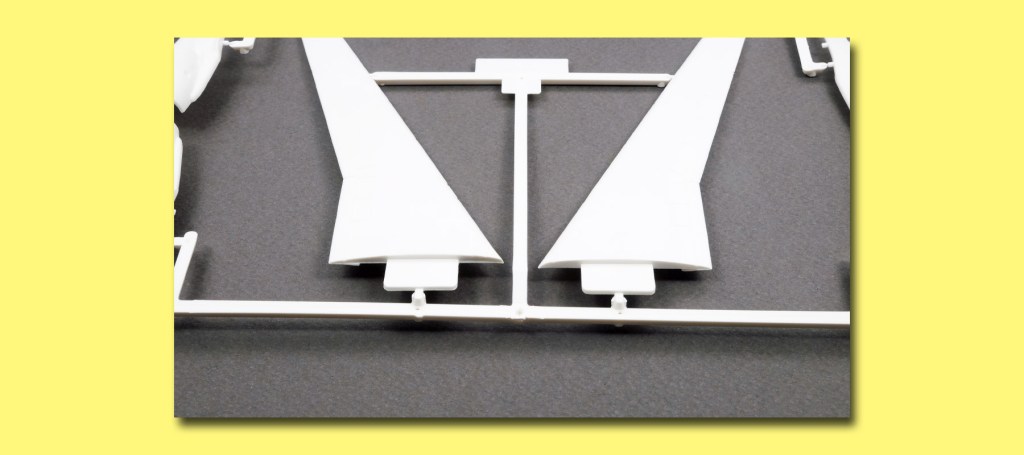

Failing that, sturdy tabs from the wing – and here it is good if both the top and bottom parts contribute to the tab. It also helps if the wing is closed with a surface that mates to the fuselage.

Worst of all is the flat surface to flat surface with no tab. here you simply must make wooden or metal wing spars from tubing and drill and pin the fuselage to take them. It is surprisingly easy to get the geometry symmetrical and the benefit of stopping wing droop over time is there from the start.

I use Contacta or Mr Cement Deluxe for this structural bond for sheer strength. Were I to do resin aircraft I would use epoxy.

Leave a comment