And it works.

I tried a new technique in the construction of scale model parts. I needed a hollow engine cowling for a bomber and had a similarly-sized one to use as a master model. A few weeks ago I embedded this master in a casting box made of cheap cardboard and poured two-part silicone in to make a flexible mould.

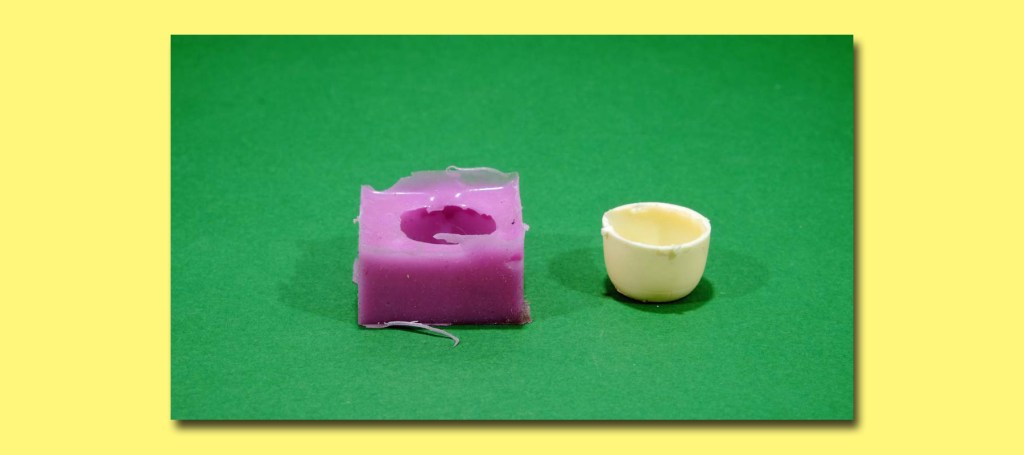

The mould having set very well, it was able to pluck the master plastic part out and was left with a perfect negative of it. The bottom of the mould…the nose of the cowling…was left closed with a cardboard sheet.

Rather than just dumping in a mix of polyester resin to produce a solid casting I resorted to a very old technique that had been used for pottery and iron casting in the early days; slush casting. It enabled me to make the final product hollow – just like the original styrene part.

When ready to go, I mixed equal parts of the polyester resin quickly and poured a good dollop into the mould. I then turned that mould over and over in my hands in the manner of the big drum of a concrete mixer. The resin is a quick-setting material and was gelled up and setting within three minutes. Once firm, it could be left to harden undisturbed. If the first slush was not leaving a thick enough coating, you could put in a second layer within five minutes.

After a full 20 minute cure, the silicone rubber mould was flexed off the part and it came out perfectly. No bubbles and no weak spots.

I was so relieved, as we were videoing this for a demonstration, and it was the first time I’d done it.

Don’t tell anyone that…

Leave a comment