Well, it worked in Burbank – it’ll work in Bull Creek.

I tackled the Lockheed Ventura in two club meetings as well as here at home by the simple process of parcelling it out into sub-assemblies and assigning them to places where the work could be done with the most facility. This was exactly the process for wartime aircraft production. I should have welcomed a Rosie Rivetter…

As it was, the nose was a serious question. Would a clear piece mask up well enough to serve for a major fuselage part? Did it fit well enough on a sleek Lockheed codfish fuselage? Only time would tell.

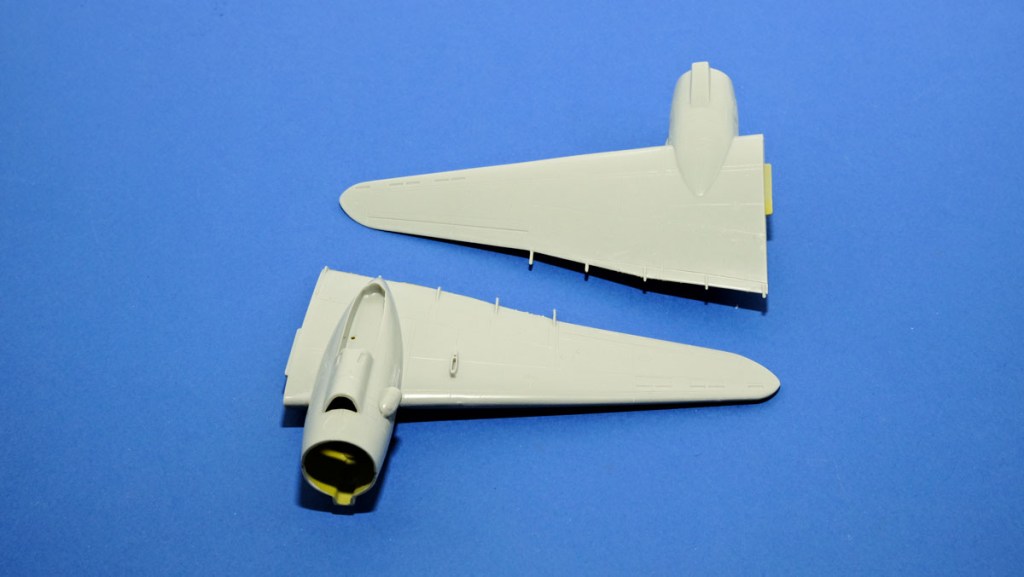

The wings slotted together perfectly, even to the trailing edge flap actuation extensions. I was prepared to lose them but they stayed on pretty well.

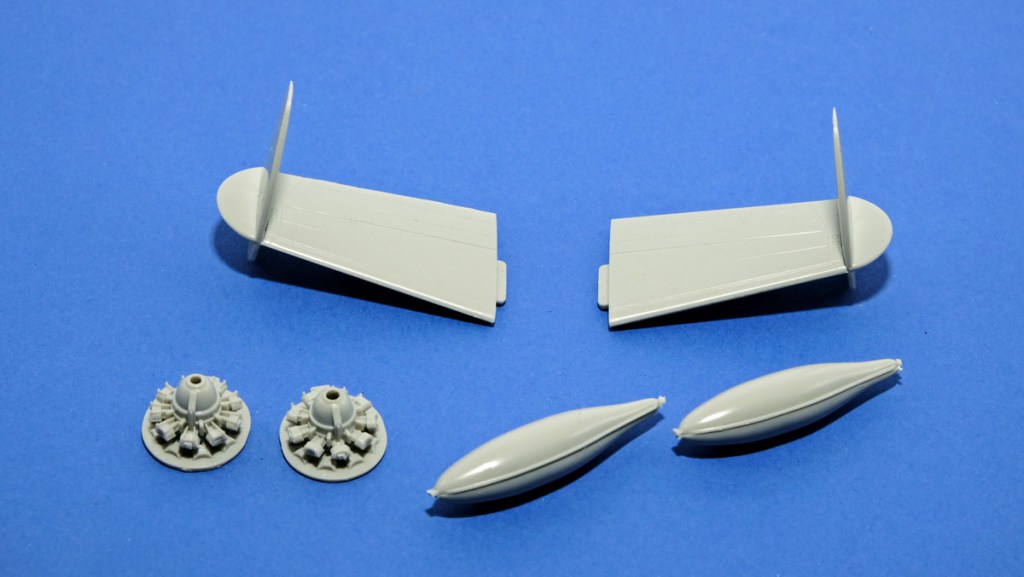

Eben the rudders were cooperative – the fit to the horizontal stabiliser sections was very precise. Dry-fitting confirmed that the stabs would form a straight line when offered to the fuselage. No pinning needed.

The engines are commendably simple and as they will be deep in cowlings there is no need for extra push rods or spark wires. I’m at the age where I sleep at night…

Leave a comment