Whenever you make a scale model kit, someone is going to be lazy. It’ll either be the designer or you.

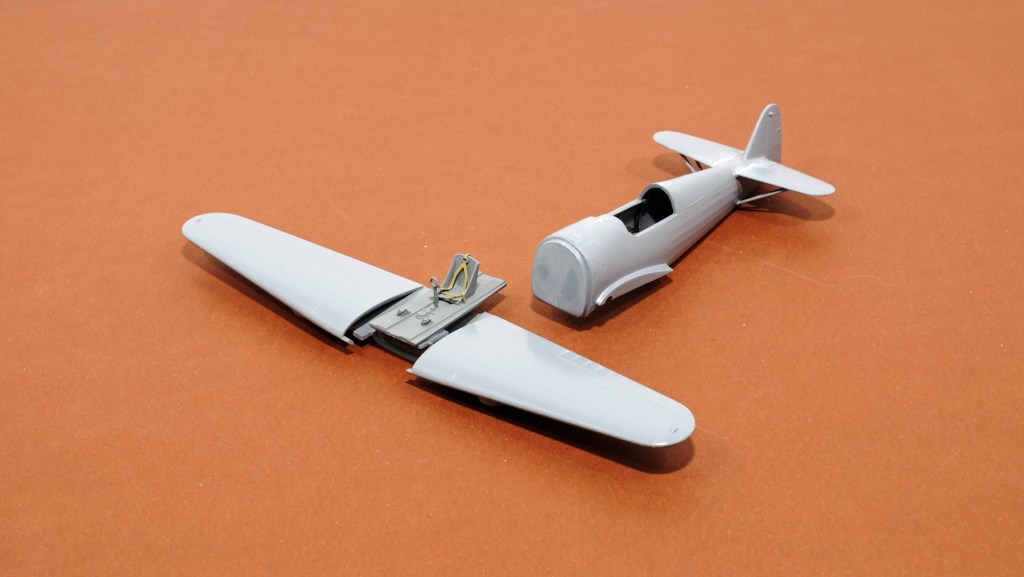

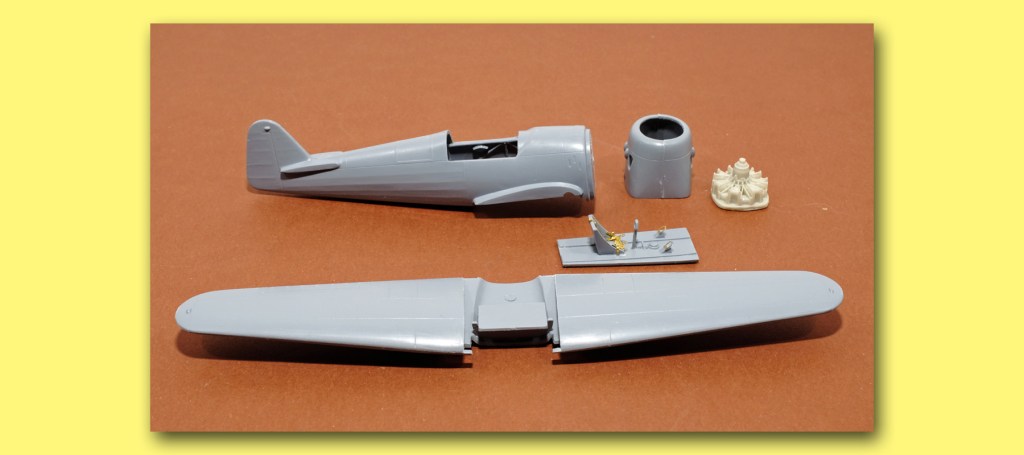

In the case of the Azur Koolhoven Fk 58 the designer has done the hard millimetres so I can cruise along. The cockpit pan holding all the detail parts can be inserted after the fuselage halves are joined and smoothed. Indeed, the pan rests on the top of the wing under-structure.

This means the business of trying to juggle three parts plus a tube of cement is largely avoided. It is not possible with some designs, but when it can be done it is a delight. There are very few gaps in the wing roots that will need attention.

The streamlined teardrops on the engine cowling are a bit of a puzzle – surely not beyond the capability of the mould-cutter to make them integral with the injected parts. However, they went in and the resin engine could be sanded to fit.

When it comes time to do the painting layers I’ll tack the cowling to the fuselage temporarily with Micro Liquitape. That way the patterns can line up – though the colour call-out has some pretty severe breaks just there. Perhaps the factory was in the habit of painting the parts separately and just bolting them on regardless.

Leave a comment