And every one of them working…

The next time you hear someone blithely tell you that they ” winged it “…and make out that it was all so easy…refer them to me. I have winged the Tupolev TB-3 and I know what the abyss looks like.

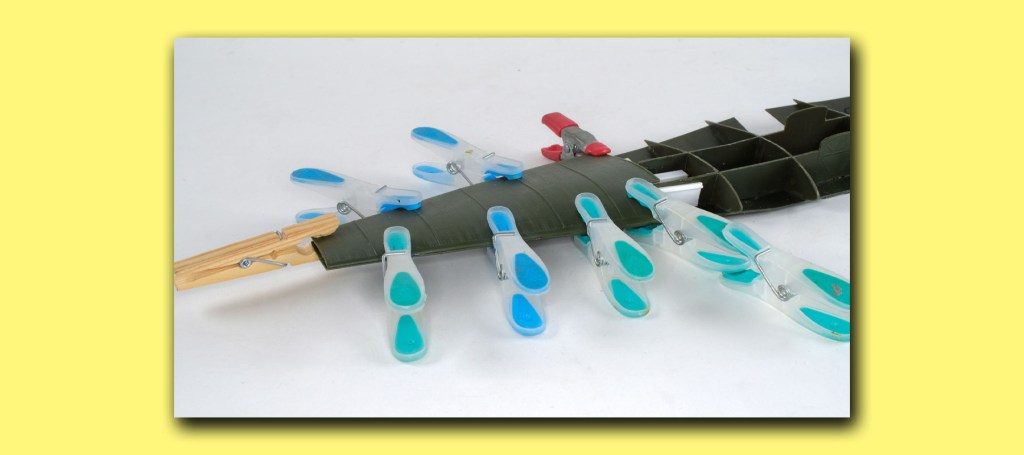

The basic bracing inside was actually very precise – so much so that the slots had to be eased considerably to get the lattice to close. It made a very sturdy structure.

Confidence in this broke down when the external struts were cemented and the sheeting began – the thing had to be sawn apart and re-braced with Evergreen box-beams. Otherwise the wing extremities would have been canted away from the dihedral. As the sheeting proceeded some of the rib formers needed marked trimming to allow sheets to meet.

The basic problem started in the ICM factory – I suspect their moulding machines have a limited size and cannot do a full-length wing – as a more advanced moulder like Academy could do for their Boeing B-29. The shed was going to be built up sheet by sheet.

In the end there were anomalies that were filled with styrene sheet and strip. I am satisfied that the nature of a 30’s Soviet plane used by the 30’s Chinese would have a limited precision in the field – so the result is not unpleasing.

Leave a comment