I am fairly bright for a dim person. I can play Scrabble and do connect-the-dots puzzles. I have, on occasion, found Wally. But I struggle with the instruction sheets for the model airplane kits.

It was not always thus…in the 1950’s and 60’s the instruction sheets for the kits seemed to be a lot easier to follow. Granted, there were some pretty crude kits then, but I cannot remember having to resort to analysing the box art or to going to the local technical library to figure out where the un-lettered scoop seen in the diagram was really supposed to go. We did not have computers or the internet then, but we had a tech library with shelves full of old RCAF service books and instruction manuals.

Some kit makers are fine – I have seen the instructions issued with Wingnuts kits and stand in awe of the job they do. Pictures, diagrams, claer written instructions…could not ask for better.

Some are woeful. I am thinking of extremely small-run kits from makers who approach English with a phrasebook and a shrug of the shoulders. I have learned not to trust the text.

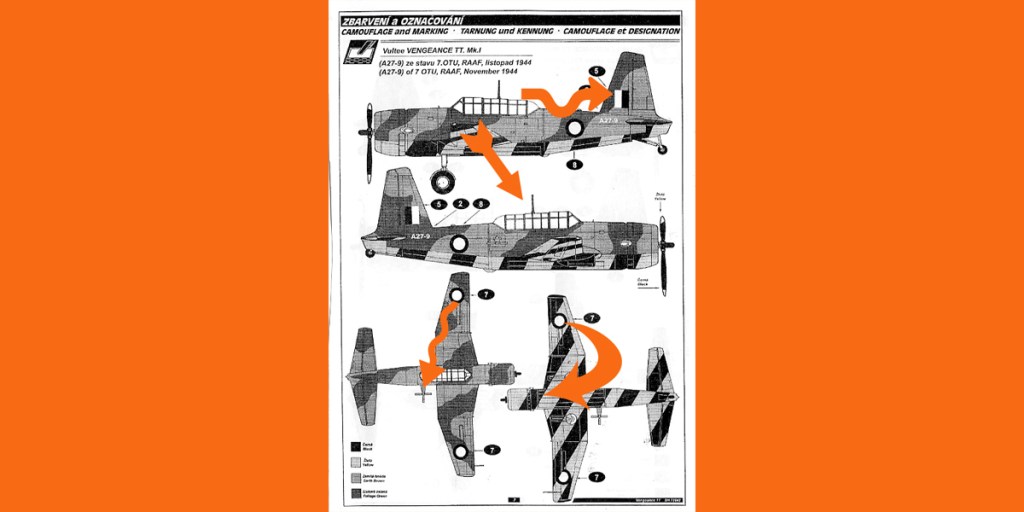

The matter of diagrams is also a fraught one. Some diagrams are extremely good – I particularly like the ones that detail each sprue and warn you against using spare parts or things meant for other variations of the basic airframe. I do not dive at the sprue and cut off all the unwanted things straight off – but I find myself referring back to those pictures frequently in a build if the subsequent detail drawings have not been done well.

Some diagrams are simple. It is hard to go past the one showing the horizontal stabilizers being glued into the tail. If the manufacture has had the foresight to make the tabs on the stabs of different widths – thus handing the flying surfaces – it is delightfully easy and reassuring.

Some diagrams are hard, where the artist intends to convey a particular position for a part, but makes it fly into that spot through other parts…rather like a circuit diagram.

Some are, well, wrong. I have caught several howlers from several kits that only showed up at the dry-fit stage. I am glad I took the time to test and try before cementing something up and trying to do the impossible. The infuriating thing about this is the realisation that the kit left the factory, went to the importer, distributor, retailer, and me before this was picked up. And a glance on the box can show me that the thing has been sitting there for a decade or longer with that same error ready to strike.

I am going to start a project – each time I find a howler, whether it be a diagram , illustration, or written error, I am going to send a correction to the manufacture. I shall not be mean about it, as I realise that many people deal with English on a different level than I…but perhaps a gentle correction may make its way into future releases. I am prepared to be a proof reader for anyone in any scale.

Leave a comment