My return to scale aircraft modelling these last few years has brought me into contact with one of the most interesting materials on the market – polyurethane resin. It is not the first time that I’ve dealt with building plastic – I worked with acrylic polymers and monomers as a dentist for 40 years and pink and white plastic hold little terror. Yet I am not all that sure about the polyurethanes.

I guess I was bitten in the arse by a Czech model of an Avro Anson in 1:72 scale. Ansons were built as cloth airplanes on a tube framework and the fuselage support inside is a mass of it – and you see it all. The Czechs decided to mould it in resin in the small scale and then ask the builder to trim a spaghetti mass of flash and bend the leftovers into an Anson. Mine was neither square nor plumb nor easy to do, and I was never so glad to see anything be buried inside a fuselage in my life. My later experiences with Airfix and Italeri kits with injection-moulded interiors have been much more pleasant.

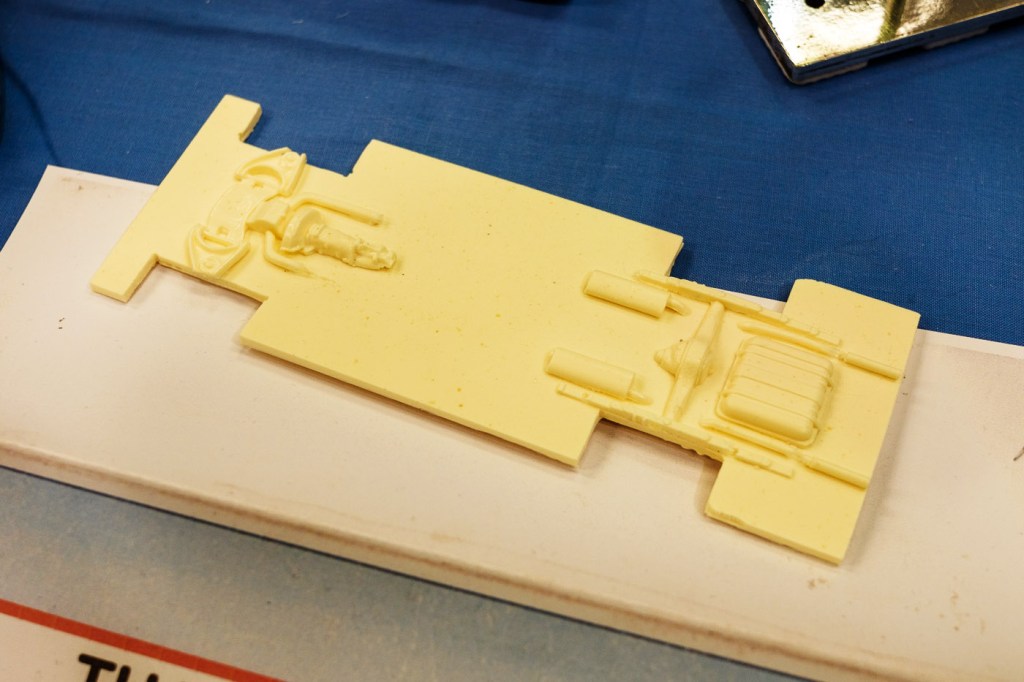

However, there is life after resin frameworks after all. The material can be poured into much bigger moulds and with a bit of care in the casting and de-flasking, a very sinuous car body may result. of course, it all depends upon the initial master model being a good representation of whatever the resin will be, but there are a lot more model sculptors of talent than you’d realise. I think some of the people who make their own castings and kits are unaware of how much spatial talent they have until they get out the final result.

I noted at the Model Car Spectacular that there are custom moulders as well as what look to be small workshop kits for sale. Subjects that would never attract a mainstream producer are possible due to the short-run nature of the resin mould.

This in turn attracts the expert modeller who may have passed through all the regular commercial kits and needs to branch out.

There are precautions to be taken with resin to prevent inhalation of the dust you make when you cut and sand it – but they are effective. Masks and wet cutting do most of the trick as well as extractor fans. No-one need fear resin if they are sensible.

However – sensible sometimes doesn’t seem to be a word that some makers use when they assign parts for a kit to a resin, rather than injection, mould. I look at any resin parts on the aircraft I build and decide whether they are really sensible and contribute enough to the overall effect to justify the fiddly work.

Some Czech kit makers are nothing but smart-alecks …I mean…an RF loop antenna for 1:72 in resin casting? Really? Just a pissing exercise. I own a pair of pliers, some copper wire, and a wooden dowel. Nevertheless, when used for components that will benefit from the properties of the material, the results are wonderful.

Leave a comment