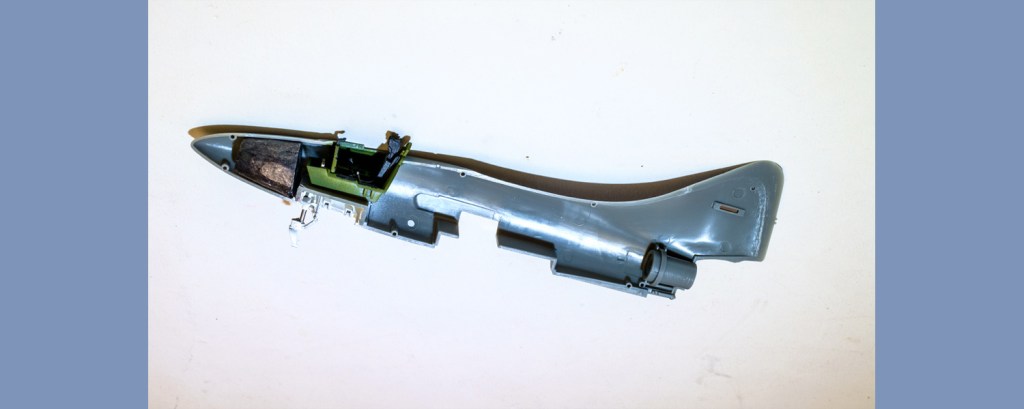

Putting together a model of a jet airplane is pretty straightforward in comparison to a biplane or a WWII bomber. Fewer parts, no propellors, and usually a much sturdier undercarriage. But there is one thing that most modern jets have in common – tricycle landing gear and a tendency to sit on their tails. The modern plastic kit is heavier in the back than the front and there’s no jet engine inside to make up the difference. So we have to incorporate a weight in the front of the plane.

I have favoured lead blocks in mine. I’ve a tin of old musket balls that can be hammered, cut and sawn to shape. With a bit of practice you can pound the ball into a pretty good fit inside the nose and get away with the minimal pressure on the front landing gear strut. Still, at some state of the game I’m going to encounter a nose strut that is just too flimsy to take the weight – and then I’ll have to box a bit cleverer.

There are few aftermarket sets of metal landing gear available here in Australia so that is out – it would not be economical under any circumstance. So I plan to fasten a length of piano wire from the wheel bay to the bottom of the wheel, just beside it. With a bit of luck it can be disguised with some paint and will bear the weight required.

Final image for the day shows just how essential Foamcore board has become in my workshop. I cut it and pin it for dozens of jigs and holding tasks. It has even become the core structure for a new camera case – that started as a rescue attempt and then became a make-do exercise. I’ve now come to see it as a better design than the commercial camera bag it replaced.

Leave a comment