I think one of the nicest things about the new Airfix kits is the way that they have decided upon the subassembly moulding. In the case of the Lancaster they’ve done something that I have not seen before…but would like to see again.

The point of assembly for many aircraft builds that makes me nervous is the bit with the engine. Oh jets are fine, as long as the engine is truly buried in the fuselage and you see it by hints. But propellor aircraft can be made or broken by the way the prop sits on a motor and the way that motor is imbedded in the cowling. Get a separate radial engine off line from the plane’s axis and the prop shaft and plane of the propellor looks all wrong – and people are surprisingly sensitive to even the slightest variation.

Inline engines might be easier if there is a simple shaft attachment for the propellor, but if the kit designer gets all arty and funny with spinning props and metal shaft you can end up with a clumsy subassembly to try to mate with the front of the engine compartment. Hobby Boss and some of the eastern Europeans are chief culprits in this. To be honest. a fixed prop at the right angle is far better than a spinning one that wobbles and flops.

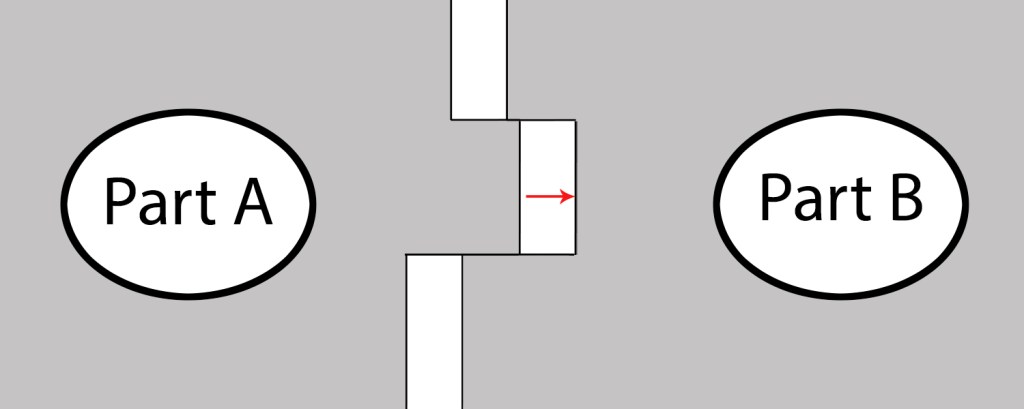

AIrfix have made a clever compromise for the front end of the Merlin engines; a separate piece with air intake and propellor support is provided.It means that you can paint the various parts, assemble them correctly while you can see both sides of the shaft, and then pop them on after all the rough handling is over.

Rather like the practice of painting the canopies and landing gear separately and then attaching them. If you can do it, you end up breaking fewer of them.

Leave a comment