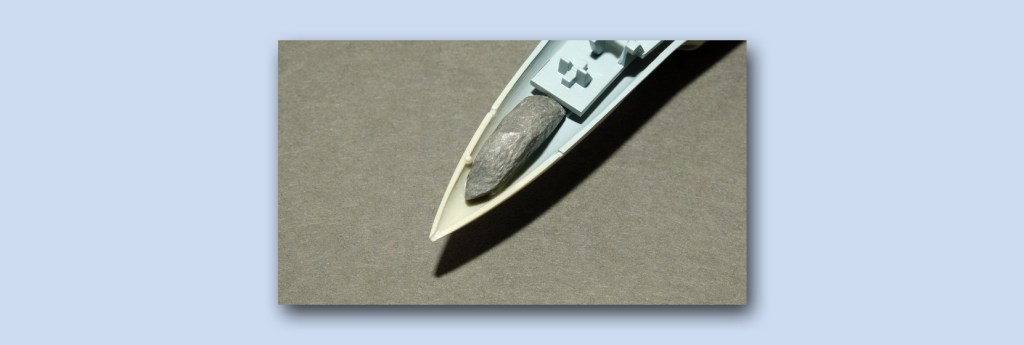

In every state of the Union and nearly every country of the world, the heading image would raise little interest; it’s a toy airplane with a lead weight glued in the nose.

In California, I suspect, it would cause sirens to wail and lawyers to leap from their kennels. Lead! A known carcinogen! A dangerous element! A Substance! Sound the Toxin Tocsin!

Well, the Little Workshop in the Little Shed is not located in Little Hysteria AKA California, and does not take much notice of their legal theatricals. There’s lead in the nose of a lot of the Air World aircraft and it is going to stay there – at least I hope it is – the PVA glue needs to remain solid.

I worked with liquid mercury for forty years, used colour developing organic solvents for ten more, and ate meatloaf in gravy in construction company mess halls before that. I am not terrified of lead. Unless it is travelling at 900 feet per second in the form of a minié ball I do not accord it much notice. I will wash my hands after working with it, but I refuse to have my brain washed every time it appears.

The business of weighting models is pretty much the province of three divisions; the plastic aircraft builder, the model train enthusiast, and the R/C ship builder. Each of them needs weight concentrated in a small space to overcome the physics of what they work with.

a. The scale airplane maker building an aircraft with a tri-cycle landing gear nearly always has more weight at the tail than in the nose – this is the kit as made. Good kit makers supply weights for the nose – or at least tell you how many grams you need in the instruction sheet. Average kit makers leave you to find out for yourself, and really bad ones fill up any spare space in the nose with plastic so that there’s no room for the lead.

You only need to forget your nose weight once and then go through the exercise of trying to insert it – or figure out some other plausible means of jacking the tail up and the nose down when the plane is finished – to teach you. Don’t close the fuselage before checking the balance – and glue that baby in there tight.

Lead formed on an anvil to fit closely into the nose is the most economic spatial solution. If you are going to be spooked by California’s environmental Greek chorus, substitute solid gold. It is heavy as well, and you do not need a certificate from Lawrence Livermore or the USAF like you do with depleted uranium.

Some people use lead shot, some use fishing sinkers. Some prise the wheel weights off cars and beat them down into the odd shapes. I use old musket balls left over from being a muzzle-loader shooter. Traditionalists and British modellers may wish to steal the lead off church roofs – or they can chicken out form climbing and just get lead flash sheet from plumbing supply places.

Whatever the supply, the resultant weight is always best as light as can be used and as far forward as can be placed. PVA or epoxy glue keeps it in place – or if you’ve got some old Selly’s Quick Grip contact cement, that is fine.

More complex solutions like Liquid Gravity or bird shot or such are more trouble than they are worth and more expense than need be paid.

b. The model train person needs locomotives that have enough traction on their wheels to haul the train, and carriages with enough weight under them to hug the track. In the case of the latter, many kits have steel weights that fit under the frame of the coach or wagon and do the job for ever more.

Locos are tougher – the commercial ones will sometimes have a Zamac weight suspended in the body of the loco between the power bogies to pull it down. If it is a home-build There may be more space in the body to put in a lead block. These are best mocked-up in balsa or plastic clay and then invested for casting with molten lead. It’s not as scary a process as you may think, and gives a solid weight that can be small but effective.

c. R/C scale ship builders may find as the size of their vessel increases, that the water it displaces is not proportional to the weight of the model – they literally need lead blocks to force it down into the water to the correct level. I remember making a model of the USS MONITOR in fibre-glass that was so big that it needed a 15-pound lead block in the hull to float correctly. The block had two holes drilled in it and a rope handle threaded through them to lift it in and out when the model was in the water.

Bigger scale ships that need to hunker down do so with flood-able ballast tanks. Valves, pumps, and more places to start leaking…

Leave a comment