The dictionary isn’t clear on the distinction.

Either way, when I look at the design of some kits – particularly the butt joint of a thin horizontal stabiliser – I start to get sceptical. My experience of adhesives tells me that there are all too many instances when they don’t.

I would not ask long life from a furniture piece if it was held together with simple PVA glue and butt joints. Some of the butts around here would bust it in a minute.

The chair or table maker strengthens the piece with wooden dowels within the joint. They distribute the forces deeper not the wood and the thing stays together.

I have long learned the value of following this in the scale world. I keep a box of brass and steel wire offcuts as well as the tail-ends of LED components . These can be matched with micro-drills and then let into the plastic joints just like the furniture. The cement is generally a full-strength Mr Cement, Revell Contacta, or a 50/50 mixture if the butt is nearly perfect.

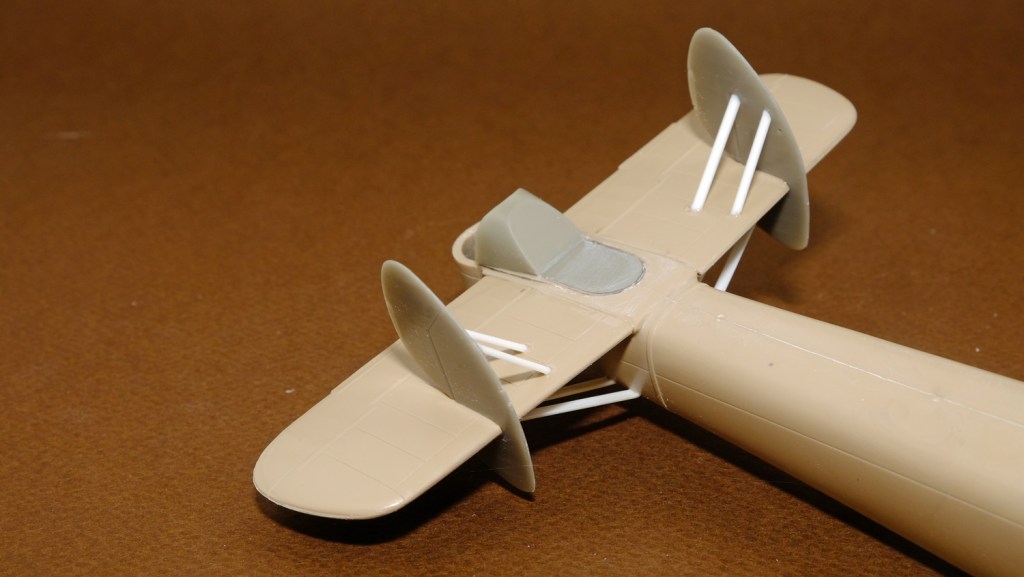

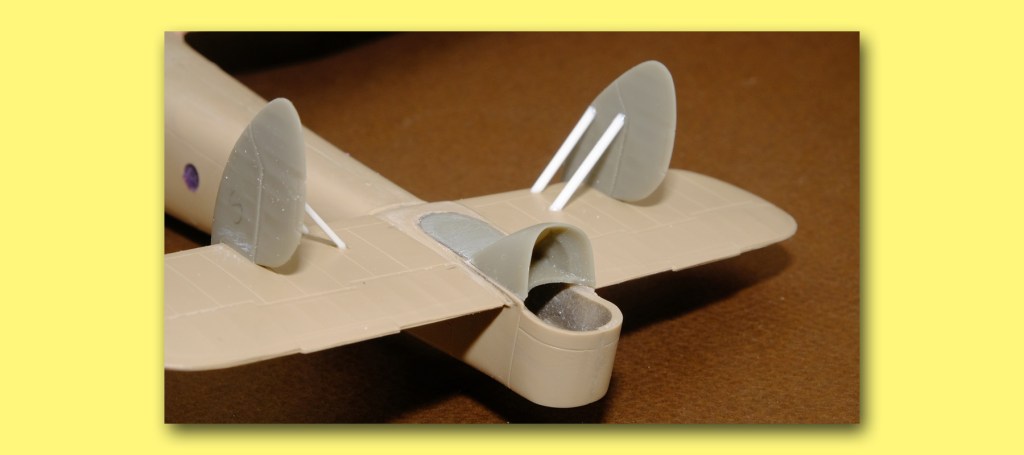

I was pleased with the Bombay, as well, to see that the Bristol designers knew they had a flimsy tail and braced it with struts, both top and bottom. This would add more to the model.

Of course I lost the struts onto the floor somewhere – they were a grey resin block – and they will show up in a month. This is scale model building, after all, and we know when we are going to have to take our lumps…

But I have Evergreen strips and they have proved fine for the purpose. Even the bit of sawing the fairing off the fuselage and cementing in the resin replacement went surprisingly well. In the end, the only Sprue Goo needed was on some distorted wing roots. I got away lightly.

Leave a comment