I’m never quite certain with superdetail, and even less so when the model kit that delivers it is on the bargain shelf.

Am I being told a tale? Will the parts come off thee sprue trees in one piece? Will they fit? Does the design of the kit follow the design of the prototype?

Roden worry me – the plastic is fine and breakable. The fit demanded is tight. And the results in the past have varied from wonderful to wonderless. Here, I think I am on the good side of the spectrum.

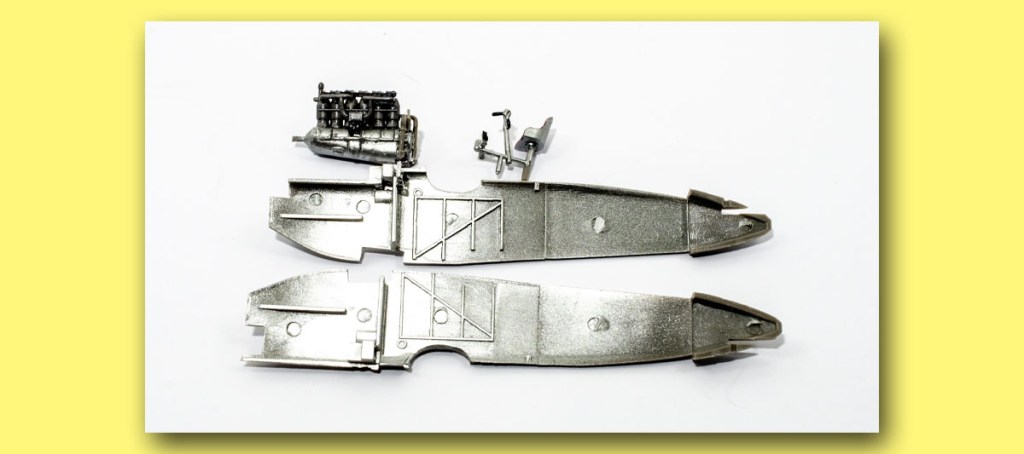

I’ve been able to get an engine together and a seat assembly that fits within the cockpit without wedging it apart. You can’t say that for some of the jet cockpit tubs and certainly not if you add one as an after-market resin item. These are detailed in themselves but something in the fuselage is going to have to go before they can drop in.

As for joining a fuselage – the one-fell-swoop school of cementation is dangerous. It will only work if there is to be no stress whatsoever on the panels as they touch. This Junkers needed to join and set firmly in the engine compartment area before the back could be bent and clamped. It’s not Roden’s fault – it is the shape of the Junkers. It will be critical when the corrugations need to match.

Thank goodness for thin cement.

Leave a comment