Tag: cockpits

-

Mirage III CJ – Part Two – The Approximate Cockpit

I confess myself mystified at the philosophy that spends money to mould a resin seat of truly superb quality and then cannot make adequate provision to anchor it accurately within the fuselage. I admit that it is unlikely to escape once the two halves of the thing are cemented together, but the business of deciding…

-

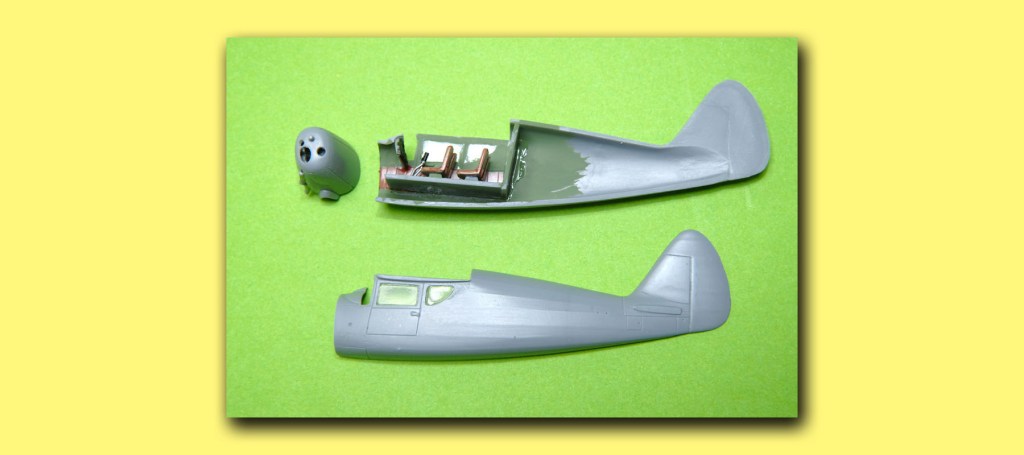

Fairchild Argus – Part Two – Inside

There are a number of sources of information for the completion of any cockpit: a. The instruction sheet. Good luck there… b. Internet images of service aircraft taken in the past, before colour film was widely available – good luck there again. c. Internet images of current aircraft in museums. Some photographers, like Inch High…

-

Sikorsky H-19 – Part Three – Squish

I don’t know if joining the two hull halves is a stressful time for ship modellers. Listening to the noise from the bench at my scale model club would suggest that it is. I can feel their pain – I experience some of it each time I join two fuselage halves. Depending upon where the…

-

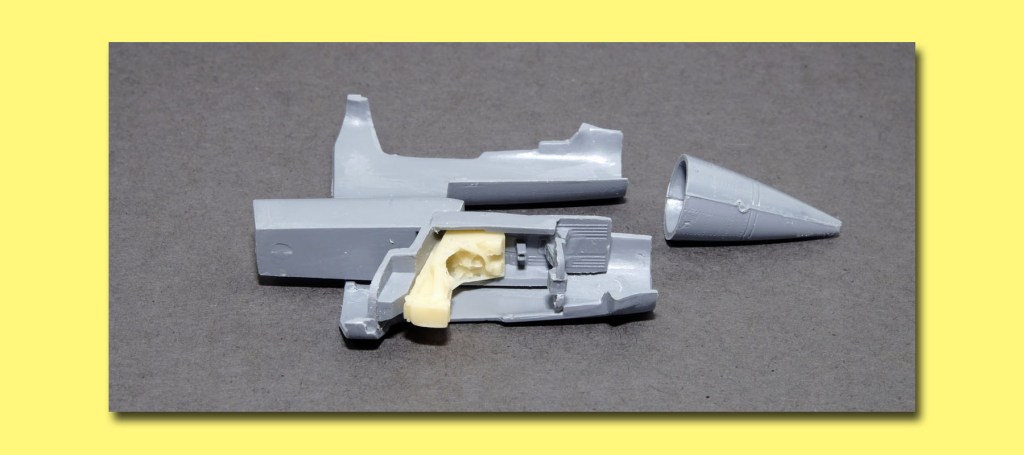

MiG 15 Bis – Part Two – The Profi Parts

Well, you could avoid them, but then you’d be wasting your three dollars. I mean the business of using the Profi-Pack parts for an Eduard kit. The difference between the Weekend Edition and the Profi-Pack seems to be masking, decal choice, and a PE brass fret. The kit makers do provide plastic parts as alternative…

-

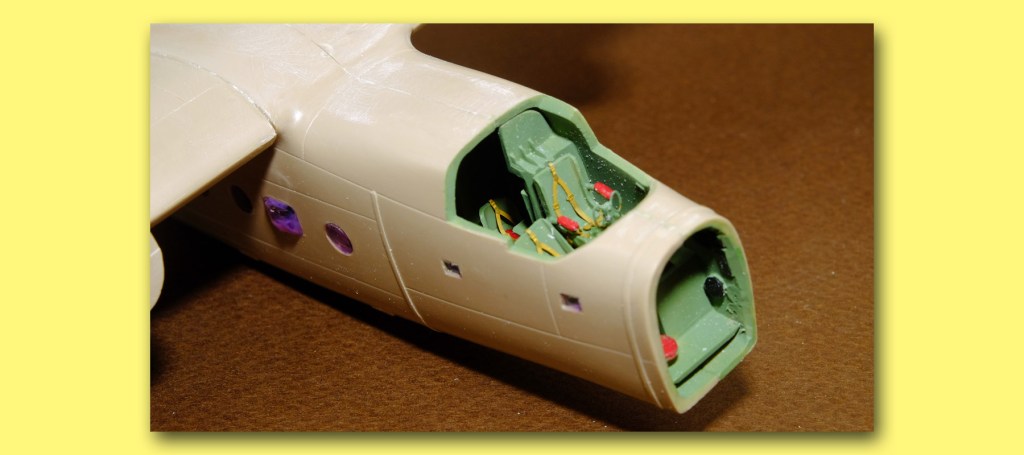

Potez 63-11 – Part Two – Having A Fit

A tight fit. The Azur model of the Potez 63-11 is probably fairly old in the Czech modelling world. I think the firm that makes these models has retired the name in favour of their ” Special Hobby ” marque. This one is from the multi-media days of styrene/resin/brass. So far the fit of the…

-

Fairey Battle Mk I – Part Three – Got It Taped

I have been trying a new procedure in my aircraft builds; dry-taping. It is at the dry-fit stage and allows me to build up a phantom of the cemented assembly and add more parts to it. I can catch cockpits wedging the fuselage sides apart before committing to them – it is hard enough sanding…

-

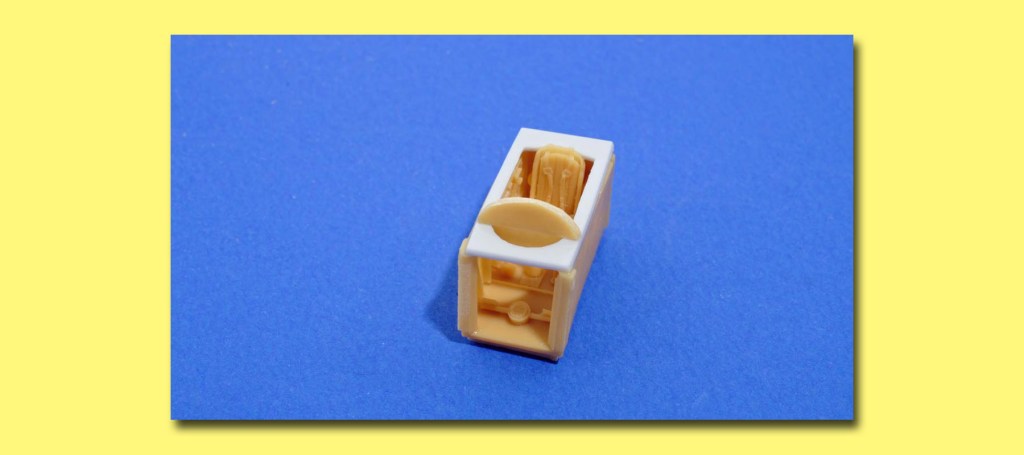

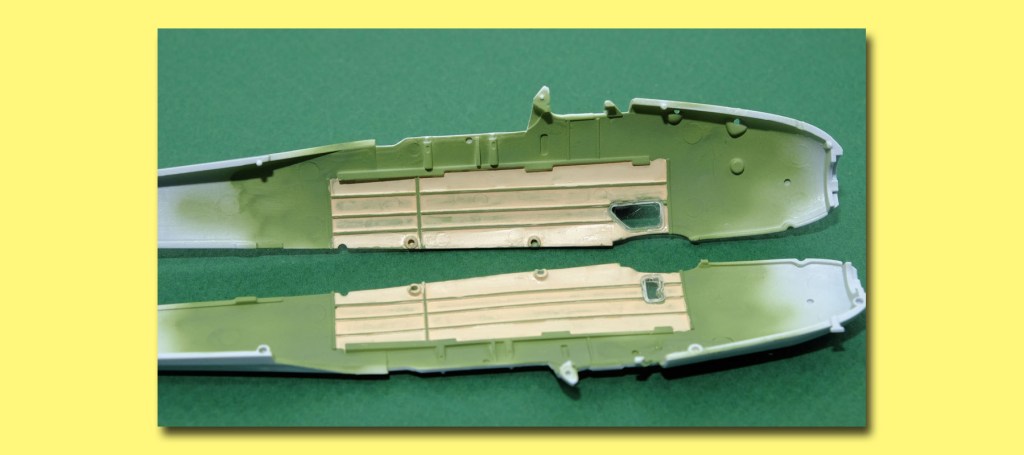

Fairey Battle Mk I – Part Two – The Paradox

How can a short-run moulder be so good at making injected parts… And then make so many bad resin ones; detailed resin panels that are meant to fit precisely. ” Meant ” is a curiously elastic word. I have been making two cockpit tubs from this Czech kit – they involve sides, back and top…

-

Bristol Type 130 Bombay – Part Two – The Inside Job

I’ve learned to do as I’m told…mostly. I do pay attention when the makers of a kit instruct me to build the aircraft cockpit first. Dropping one in after the fuselage is joined is very rarely an option. It can be done with some Soviet fighters where there is a large opening at the wing…

-

Fairey Swordfish Mk I – Part Two – If We Are To Believe…

I am often asked to believe – but I pause before I do. It is not that I think people duplicitous – it is just that I know there are only limited methods of actual proof – sight, touch, smell, etc. Thus I regard the colouring instructions in model kits with care. Do the writers…

-

Vought Crusader F-8 – Part Two – Cockpit Decals

Bless the designer who thought of making decals for the cockpits of 1/72 scale aircraft. I admire the resin parts that people buy for aftermarley – they can be superbly detailed. A worker in 1/48 and larger would certainly get good visual value from a resin seat or control stick. And the PE brass instrument…