Category: subassembly

-

Me 262 – Part Two – How Wrong I Was

When I saw the flash flooding around some of the Revell parts for this jet fighter I though that I was in for an epic of cutting and sanding. As it is, there has been little fettling needed and by the time it has progressed from dry fit to cementation, no filler gaps are to…

-

Potez 63-11 – Part Three – The Problem

Solved. Until the next one crops up. The fuselage, wings, and tail of the Potez observation aircraft are together and the amount of filler is absolutely minimal. I have undercoated and smoothed it, and could not be happier. In the intervals of waiting for things to set or dry I tackled the engines, wheels, landing…

-

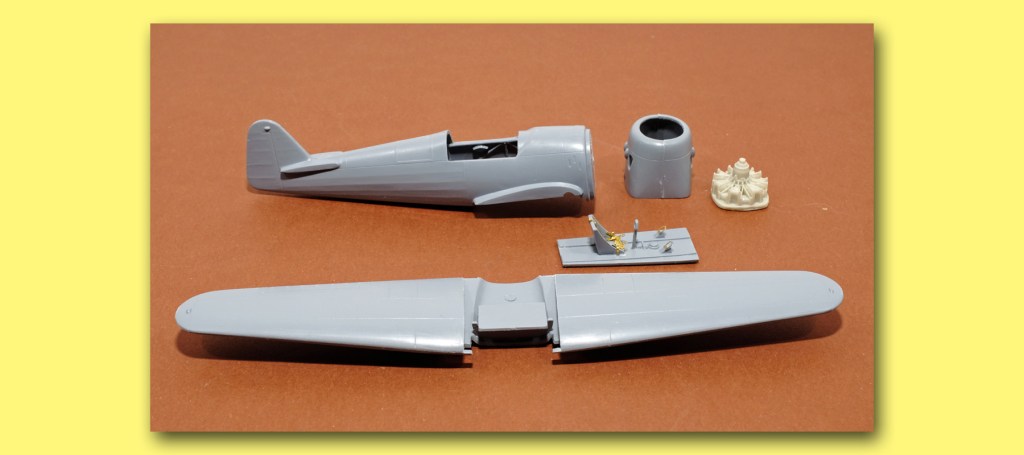

Potez 63-11 – Part Two – Having A Fit

A tight fit. The Azur model of the Potez 63-11 is probably fairly old in the Czech modelling world. I think the firm that makes these models has retired the name in favour of their ” Special Hobby ” marque. This one is from the multi-media days of styrene/resin/brass. So far the fit of the…

-

Koolhoven Fk 58 – Part Three – When Disaster Strikes

Don’t roll over – Strike back. Firstly, don’t panic. Nothing that you can do to a plastic model kit will kill anyone or bankrupt you. You can lay the worst result down in the rubbish bin, walk away from it, and go with new knowledge that could not be got any other way. It’s like…

-

Koolhoven Fk 58 – Part Two – Ease Of Construction

Whenever you make a scale model kit, someone is going to be lazy. It’ll either be the designer or you. In the case of the Azur Koolhoven Fk 58 the designer has done the hard millimetres so I can cruise along. The cockpit pan holding all the detail parts can be inserted after the fuselage…

-

Consolidated B-24 D – Part Three – Take That, Ya Basket!

A new selection of things to add to my least-favourite kit experiences. Don’t get me wrong – after smoothing the lumpy exterior of this old Revell casting, the parts have gone together pretty well. I used the progressive cementation method and the workshop clamps coped with the complex forces needed – the fuselage and wings…

-

Consolidated B-24 D – Part Two – The Toxic Rivet

Or should that be noxious? Whatever, the exaggerated rivet detail on this old Revell kit is probably what causes it to be rejected by the modern builders. Yet, under the spotty exterior is a pattern of decent engraved panel lines. I researched other’s efforts and found one ambitious chap who sanded the rivets off entirely.…

-

Lockheed Ventura – Part Two – Assembly LIne

Well, it worked in Burbank – it’ll work in Bull Creek. I tackled the Lockheed Ventura in two club meetings as well as here at home by the simple process of parcelling it out into sub-assemblies and assigning them to places where the work could be done with the most facility. This was exactly the…

-

Discover the Joy Of…

A recent advertisement on FACEBOOK* told us to discover the joys of building a ship model. Fair enough. There are people in our club who do just that – build wooden and plastic vessels – and it has been a joy to see them at work. Watching them search the grey concrete floor for a…

-

Junkers D.1 – Part Three – Gerry And The Wrinkles

Sounds like a geriatric pop group, doesn’t it? In this case it is good old Junkers and their good old metal folding mill. They had an idea and they stuck to it, and we are stuck with it. Don’t get me wrong – I understand the principle of the corrugation and applaud it in fences…